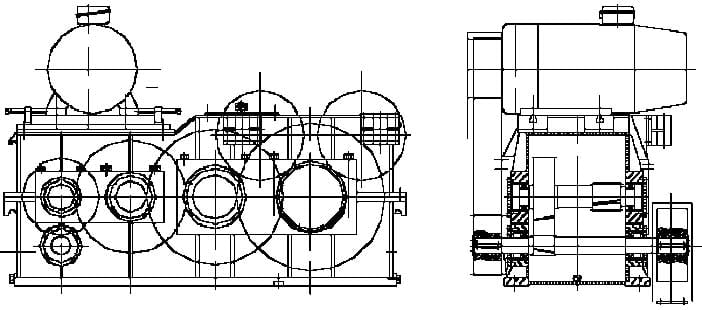

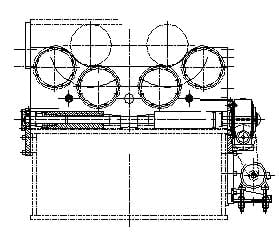

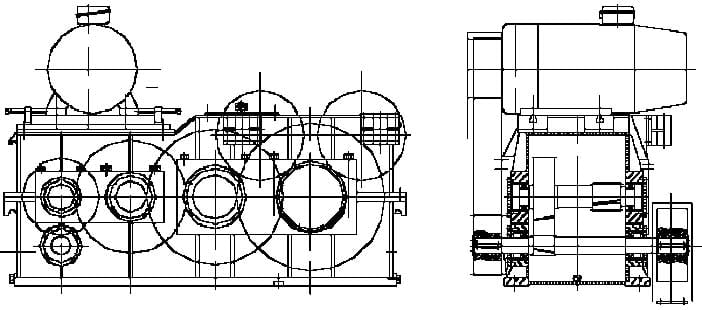

Roller device

The roller device is composed of a silk screw mechanism, inclined wedge mechanism, idler, and so on. The roller is made of 45# steel, quenched and tempered, and the hardness is HB190-220. The surface hardness of the roller is lower than the surface hardness of the lower roller, and the surface turns a spiral groove, which effectively prevents the next tired oxide, and the roller is damaged due to impurities. On the surface, the idler can be adjusted up and down and adjusted up and down according to the size of the rolled sheet.

Both ends of the idler roller adopt self-aligning rolling bearing with low frictional resistance. From thin plate to thick plate, the rolling range is wide.

Main Drive

The main transmission consists of a main motor, a V-belt, a spur gear reducer, and an electrohydraulic actuator brake. The main drive can be reversed to provide power for the rolling of the sheet.

The main motor uses three-phase asynchronous motors for lifting and metallurgy.

The main reducer adopts Q235-A steel plate weldment to perform stress treatment.

turn over device

The overturning device is composed of an overturning frame, a ram, and an inverted oil cylinder pin. The single-stage cylinder is used for the overturn cylinder and the piston rod of the overturn cylinder is chrome plated. The tipping device tilts the inverted side frame to facilitate the removal of the workpiece in the axial direction of the roller and completes the unloading step. After the rollover frame is reset, the next workpiece can be processed.

Fixing, Overturning Side Frame, Chassis, Fixing, Overturning Side Frame, Chassis Welded Steel Plates, CO2 Gas Shielded Welding, Postweld Annealing Stress Removal, Shot Blasting.

The fixed, inverted side frame is used to house the two main cylinders.

The chassis adopts a frame structure, which has a high torsional cross-section coefficient, fewer anchor bolts, and convenient installation and debugging.