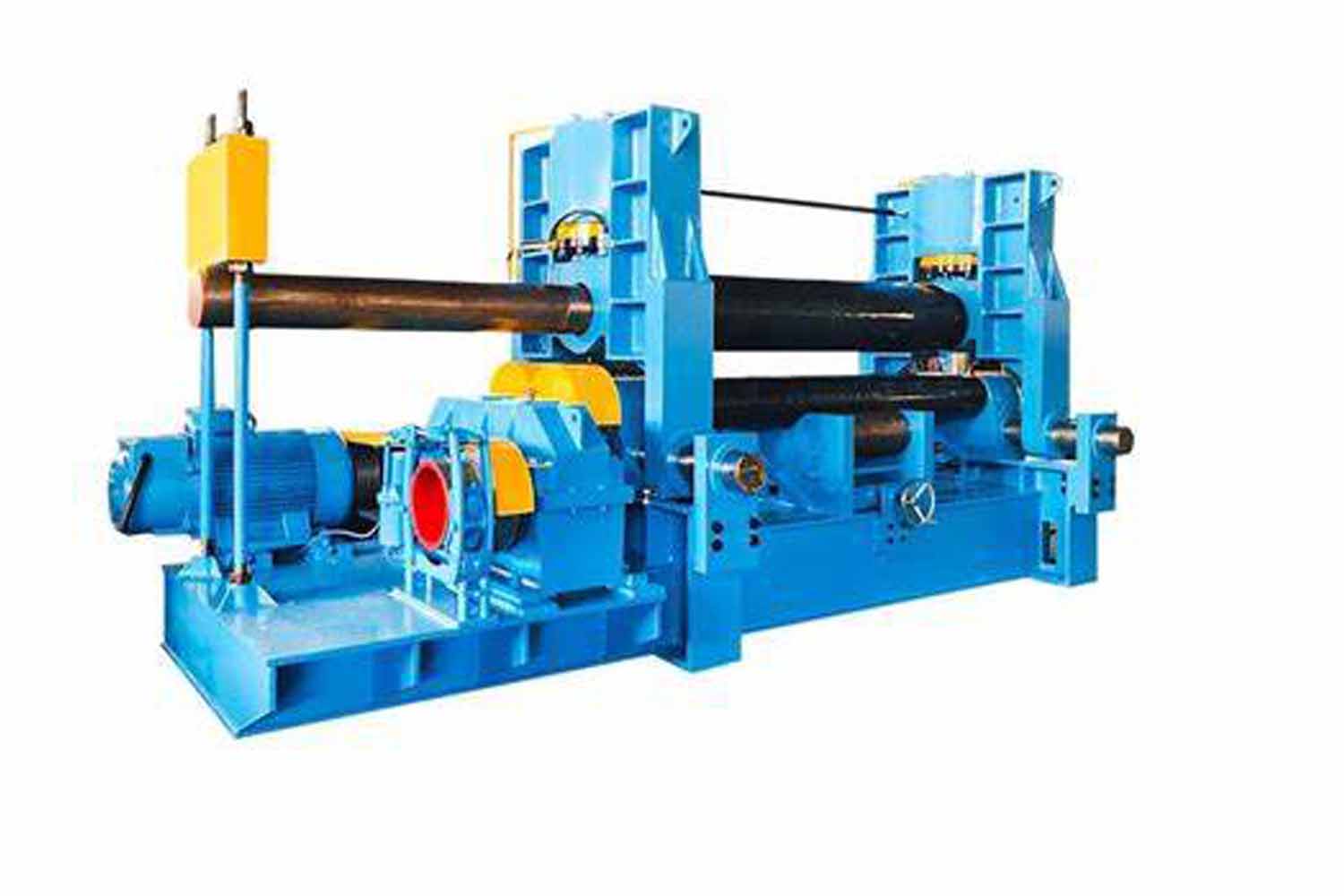

Plate rolling machine is a general equipment for bending metal sheets into cylindrical, arc-shaped or other shaped workpieces.

Plate rolling process is based on the principle of three points forming a circle, using the relative position changes and rotational motion of the workpiece to cause continuous plastic deformation of the plate to obtain a workpiece of a predetermined shape.

Plate rolling machines are essential tools in metalworking and fabrication industries, used to bend and shape metal plates into various forms. While these machines are robust and reliable, they can encounter operational issues from time to time.

Top 4 Common Problems And Solutions

Uneven Rolling

Problem: Uneven rolling, also known as coning or “dog-boning,” can result in curved or distorted workpieces.

Solution: To address this issue, follow these steps:

- Check Alignment: Ensure that the three rolls (two bottom and one top) are perfectly aligned. Misalignment can lead to uneven rolling. Adjust the rolls as needed.

- Material Thickness: Verify that the material thickness is consistent throughout the entire length of the plate. Variations in thickness can cause uneven rolling.

- Roller Pressure: Adjust the roller pressure based on the material thickness. Lower pressure for thinner materials and increase it for thicker ones.

- Operator Skill: Adequate operator training is crucial. Inexperienced operators may mishandle the machine, leading to uneven rolling.

End Flare

Problem: End flare is when the edges of the plate curl up during rolling.

Solution: To prevent end flare, consider the following:

- Rolling Direction: Start rolling from the center and move outward to minimize end flare.

- Material Quality: Use high-quality materials with even thickness to reduce the likelihood of end flare.

- Proper Setup: Ensure the machine is correctly set up, with the side rolls positioned at the correct angle to prevent curling.

Slip or Skidding

Problem: Slip or skidding can occur when the plate does not grip well between the rolls, leading to inconsistent results.

Solution: Prevent slip or skidding by:

- Surface Preparation: Make sure the plate’s surface is clean and free from contaminants, ensuring better traction.

- Roller Texture: Check the texture of the rollers. Smooth rollers can cause slippage, while textured or serrated rollers provide better grip.

- Roller Alignment: Verify that the rollers are aligned correctly, as misalignment can contribute to skidding.

Overloading

Problem: Overloading the machine can lead to excessive wear, damage, and even accidents.

Solution: To avoid overloading, adhere to these guidelines:

- Material Limits: Stay within the machine’s specified material thickness and width limits.

- Roller Adjustment: Adjust the roller pressure and clearances according to the material’s properties. Consult the machine’s manual for guidance.

- Regular Maintenance: Perform regular maintenance to keep the machine in optimal condition. Lubricate moving parts and inspect for signs of wear.

Plate Rolling Machine Troubleshooting Flowchart

To assist you in quickly identifying and addressing issues with your plate rolling machine, here’s a simplified troubleshooting flowchart :

| Problem | Possible Cause | Solution |

|---|---|---|

| Uneven Rolling | Misalignment | Align rolls properly |

| Inconsistent thickness | Check material consistency | |

| Incorrect roller pressure | Adjust roller pressure | |

| Operator error | Train the operator | |

| End Flare | Wrong rolling direction | Start from the center |

| Poor material quality | Use high-quality materials | |

| Incorrect setup | Ensure correct machine setup | |

| Slip or Skidding | Surface contaminants | Clean plate surface |

| Smooth rollers | Use textured or serrated rollers | |

| Roller misalignment | Align the rollers correctly | |

| Overloading | Exceeding material limits | Stay within machine limits |

| Incorrect roller settings | Adjust roller pressure and clearances | |

| Lack of maintenance | Perform regular maintenance |

Conclusion

Plate rolling machines are versatile tools that play a crucial role in metal fabrication. However, like any mechanical equipment, they can experience operational challenges. By understanding the common problems and their solutions, operators can keep these machines running smoothly, maintain product quality, and ensure safety in the workplace.

Remember to follow the manufacturer’s guidelines and conduct regular maintenance to prevent many of these issues from occurring in the first place. With proper care and attention, plate rolling machines can be reliable assets for your metalworking endeavors.