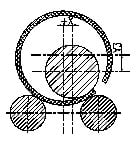

PBR-T 3-roll plate bending machine

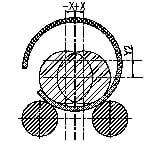

The PBR-T top roll horizontal movement 3-roll bending machines top roll crowning and adjustable Back-Up Rolls enable to achieve precise circularity and cylindricality to application with a wide range of material thicknesses, it can be used to roll bending the metal plate into different shapes such as cylindrical form, conic form, and arc.

Being formed in the procedure that top roll moves front/rear direction, the ends of the material plate are firmly bent as well as the one was done by the ordinal press. Top roll crowning and adjustment of back-up roll help correct deflection of both Top Roll and Back-Up Rolls to be more precise circularity and cylindricality of applications, which reduces the time of post-procedure.

| Project | Units | Technical Data |

| Specifications | PBR-T 120*3200 | |

| Upper roller adding pressure | T | 1600 |

| Max width of roll board | mm | 3200 |

| The length of working rolls | mm | 3300 |

| Max thickness of the plate | mm | T100*B3200*φmin4000(S355) |

| The max thickness of pre-bending | mm | T80*B3200*φmin4000(S355) |

| Up roll diameter | mm | Φ900 |

| Down roll diameter | mm | Φ520 |

| Support rollers | Set | 1 Group |

| Distance between two down rolls | mm | 1000 |

| Drive speed | m/min | about 3.0 |

| Main motor | kw | 110 |

| Moving motor | kw | 45 |

| Hydraulic motor | kw | 22 |

Structure of PBR-T 3-Roll Bending Machine

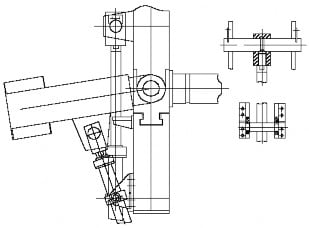

The PBR-T 3-roll bending machine should be composed of the main structure, hydraulic system, electrical control system, and cone device.

Main structure

The main structure is composed of an upper roller, down rollers and level motion device support rolls device, tuning device, balance device, lubricating device, left and right work frame, and bottom plate.

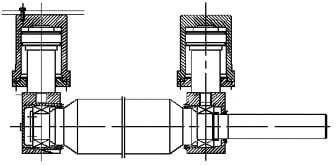

Upper roller

The upper rolls device is composed of the main cylinder, upper bearing pedestal, upper rolls, and double self-aligning bearing .two cylinders provide the pressure for upper roll bending, the main cylinder working pressure is 20 Mpa, max pressure of upper roll multiply 0.8 times to compensate for pre-bending. Upper roll two ends fit with double self-aligning bearing to reduce the friction and motor power. The material of the upper roll is 42CrMo, heat treatment is HB220-280.

Down roller

The material of the down roller is 45#, heat treatment is HB220-280. it composed of down of roll, down roll bearing pedestal, down roll input gear, down roll, glide bearing. Down bearing adopt SF-2 oil glide bearing.

Level motion motor supplies the power, through the strap drive to CWU worm wheel and pole speed reducer. Upper roll level motion drove by worm wheel and pole to finish bending in dissymmetry form.

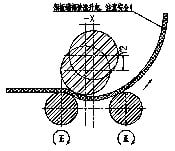

Support device

Composed of a sloping block device, support device, support rolls bearing pedestal, and support lifting device, support rolls can adjust up and down. The adjustment depends on plate speciation. The material of support is 45#, heat treatment is HB220-250, it made up in helix sharp to protect the surface.

It is composed of a motor, hard gear speed reducer, output gear, and main motor that can be tuned in two directions and provide a bending pitch of strand. ( main drive device )

Overturn device

Composed of ram, bearing, tuning cylinder

Balance device

Composed of balance compact, screw.

Lubricate device

composed of lubricating pipe and lubricate pipe attachment, adopted GB7323-1994 NO 2 lithium grease.

Hydraulic system

Composed of Y series motor, gear pump, valves, oil tank, pipe and soon.

Max pressure is 20 Mpa, testing pressure is 24 Mpa, pressure adjusted by overflow valve, system working pressure 0-19 MPa, normal pressure is 15Mpa. the valves adopted from Taiwan.

Electricity system

Composed of an electrical box, operation table, and manual button. the power is 380V50HZ adopted PLC control system code with longevity easily operate. The whole bending process can be read from the indicator set on the control box.

Digital display system

This Plate Bending Machine adopts two sets of the digital instruments and a displacement sensor formed a reliable digital display and control system。

the processes of rolling board ( Rear bending )

Step 1:send the plate in and align it

Step 2:The upper-level position moved to – X dropped to Y1 position, The reverse, make steel to forming position.

Step 3:Press down the upper roll, and rotate the lower rolls clockwise.

Step 4:Stop the upper roll to Y2, and rotate the lower rolls clockwise continuously.;

Step 5:To stop, end plate under the roller on the board, Y3 stop at the end of the direct pressure reflex;

Step 6:The upper level of ascent Y2-α , move position+ X, press the same position Y2, next roller is turning;

Step 7:To stop, the end plate under the roller, to stop Y3 position of the board of direct compression reflex,

Step 8:The upper roller X = 0, moved to the next to position Y4, the positive &negative, bending compensation.